Mathematical Modeling and Optimization of Plantain Chip Drying

A Parametric Study on Air Frying Conditions

DOI:

https://doi.org/10.54117/ijet.v1i1.13Keywords:

Plantain drying, Optimization, Analysis of variance, Tray drierAbstract

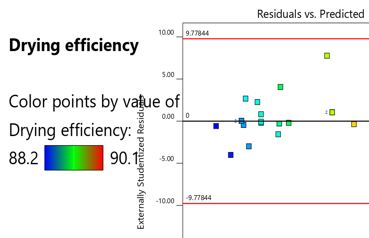

Air frying is a promising technology for the production of healthy and nutritional snacks. The process optimization and parameters analysis of the drying of plantain chips was carried out using Buckingham’s pi theorem. Studies were conducted to examine how various processing conditions affected the nutritional and sensory properties. The variables considered for the study were Drying temperature (80 – 100 °C), Air flow rate (0.25 – 0.45 m/sec), Chimney diameter (20 – 40mm), Chip thickness (0.5-1mm) while the responses were drying rate and drying efficiency. The Analysis of Variance (ANOVA) data showed that the variables affected the responses (drying rate and drying efficiency) significantly (p < 0.05). It was observed that for the optimal response values of 0.0161177 Kg/h and 88.88 % for the drying rate and efficiency respectively. The predictive models developed in the research work will be used for predicting process performance of drying plantain chips.