Effects of Groove Angles and Quenchants on the Structural Integrity of a Single-Vee Butt Welded Joint of AISI 1024 Carbon Steel Weldment

DOI:

https://doi.org/10.54117/ijet.v1i1.3Keywords:

AISI 1024 Steel, Quenchant, Welding, Structures, Hardness, CorrosionAbstract

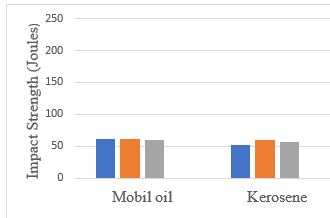

The high failure rate of welded structures has made it necessary to investigate some welding parameters that may be involved in these failures, such as groove angles, quenchants, welding current, welding voltage, and weld pass speed. This investigation aimed to investigate the impact of quenchants and groove angle on the structural integrity of a Single-V butt welded joint, using AISI 1024 steel. Nine samples, each measuring 150 x 80 mm, were cut from an 8 mm thick AISI 1024 steel plate. The findings of the study showed that, in comparison to oil and kerosene-quenched samples, the weldments cooled with natural air had significantly greater impact strength for the corresponding groove angles of 30°-130J, 45°-128J, and 60°-122J. Furthermore, out of all the groove angles taken into consideration in this study, the weldments of the samples that were cooled naturally had the highest hardness value; the maximum value of 188HBW was obtained with a groove angle of 60°. At groove angles of 45° and 60°, respectively, Mobil oil quenchant produced greater hardness values of 150HBW and 159HBW than kerosene, but at a groove angle of 30°, kerosene produced a larger hardness value of 152HBW than Mobil oil Although the observed mechanical qualities varied across all samples due to the changes in the quantities of cementite and pearlite present in the samples, the microstructural inspection studies showed phases of cementite and pearlite structures on all samples. The study's conclusions will help structural industries achieve the best possible weldment performance for AISI 1024 carbon steel