Comparative Strength of Concrete Made with Stone Dust Sourced as Fine Aggregate from Abakaliki Ebonyi State and Nkwelle Ezunaka in Anambra State

DOI:

https://doi.org/10.54117/ijet.v1i1.7Keywords:

Stone dust, fine aggregate replacement, compressive strength, concrete performance, Abakaliki stone dustAbstract

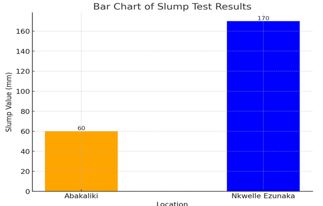

This study examines the use of stone dust in concrete production as a partial substitute for fine aggregates, using a water-to-cement ratio of 0.6 and a mix ratio of 1:1.5:3. In this study, concrete samples from Nkwelle and Abakaliki will be evaluated for the impact of stone dust on their workability and compressive strength. To assess the concrete's performance at different curing phases, important tests are slump and compressive strength tests. The slump test results showed that the concrete mix had good workability, with a value of 85 mm. We tested compressive strength at 7, 14, 21, and 28 days. At each interval, the Abakaliki samples showed exceptional performance, obtaining compressive strengths of 16.75 N/mm², 20.70 N/mm², 15.40 N/mm², and 16.55 N/mm², respectively. The Nkwelle samples, in contrast, showed strengths of 10.70 N/mm², 12.30 N/mm², 12.20 N/mm², and 13.30 N/mm² throughout the same periods. The increased cement-aggregate bonding and particle size distribution in the Abakaliki samples are responsible for their higher compressive strength. On the other hand, the Nkwelle samples had a more gradual and slower growth of strength, which could be attributed to variations in curing conditions and aggregate qualities. According to the study's findings, especially in places with scarce sand supplies, stone dust can be a practical and sustainable substitute for natural sand in the manufacturing of concrete. However, the final compressive strength is greatly influenced by elements like the quality of the material and the curing conditions. To maximise the potential of stone dust in concrete applications and encourage sustainable building practices, the research suggests further optimisation of the mix design and curing procedures.